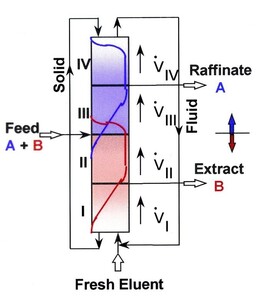

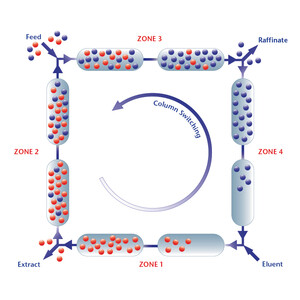

Simulated moving bed chromatography

Simulated Moving Bed (SMB) Chromatography: Unlocking Efficiency in Separation and Purification

Simulated Moving Bed (SMB) technology revolutionizes chromatographic separation by offering continuous purification with remarkable advantages over traditional batch methods. Here’s why SMB deserves the spotlight:

Explore the power of SMB – where precision meets productivity.

The AZURA Lab SMB System is optimized for the multicolumn separation of binary mixtures of small molecules in gram-scale. The SMB System A29101 is the standard stainless steel configuration of our AZURA Lab SMB. It consists of seven 8-multiposition valves and four AZURA P 4.1S included in four Assitants ASM 2.2L. The high pressure range as well as the flexibility of the multiposition valves make this system the perfect solution for SMB chromatography.

With our preconfigured Upgrade-Kits you can upgrade your SMB chromatography system very easily and build up the system you need.

System and process control: A29800 (one CORI-FLOW), A29801 (four CORI-FLOW)

Heating and column organisation: A29903 (oven), A29901 (column holder ID 50), A29902 (for columns with 8, 16 or 20mm ID)

| Recommended flow rate | 2-30 ml/min |

|---|---|

| Continuous working conditions | 3−25 ml/min |

| Recommended Feed flow | 0.1−4.0 ml/min |

| Maximum delivery pressure [bar] | 130 bar |

| Maximum viscosity | 100 cP |

| Column dimensions | up to 30 mm ID |

| Column configuration | 2:2:2:2, 1:1:1:1, 1:3:3:1 |

| Operating modes | SMB |

| Supported software packages | PurityChrom® MCC |

| Wetted materials | PAEK, FKM, GFP (graphite fiber reinforced PTFE), PEEK, PTFE, stainless steel, ruby, sapphire, Titanium, Aluminiumoxid (Al2O3), Zirconium oxide |

Do you need more information or looking for other SMB systems, for instance bio-compatible SMBs, please visit our supplier website or contact us for more information: